2 Head Linear Weigher Packing Machine with Double 2 Layer

Description

Basic Info

| Model NO. | DCS-50-D |

| Forming Function | Filling |

| Driven Type | Electric |

| Material Type | Grain |

| Packaging | Bag |

| Packaging Material | Plastic |

| Voltage | as Clients Prime; Requirement to Customize |

| Power | 220V 50Hz |

| Bag | 0--50kg/Bag |

| Speed | 600-800 Bags /H |

| Sealing Type | Heat Sealer or Sewing |

| Air Source(MPa) | 0.4-0.6MPa |

| Error | +/-0.2-0.5% |

| Electric Cabinet | CE Standard |

| Equip | Sewing Machine |

| Transport Package | EU Standard; HDF Package |

| Specification | Customizable Size |

| Trademark | YUFCHINA |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 50 Sets Per Month |

Product Description

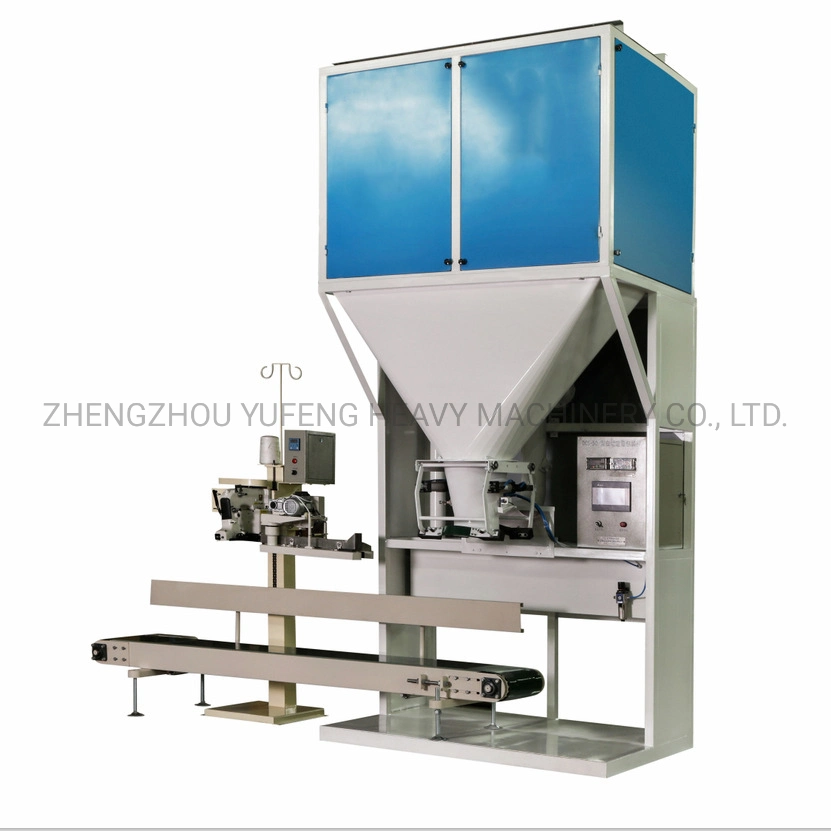

Description of Double bucket packaging machine

This kind of packing machine is designed for quantitative packaging, which is divided into double bucket packing scale and single bucket packing scale. Double bucket packing scale adopts the integrated structure, and has proper height, compact structure, efficient energy conservation, novel appearance, simple installation, convenient maintenance. The system quantitative precision is two thousandths.

Features of Double bucket packaging machine

1.The main engine adopts different speed to feed: fast, medium, slow and special feed agitate the structure. 2.Advanced digital frequency conversion control technology; sampling processing technology; anti-interference technology; realization of automatic compensation and correction.

Characteristics of Double bucket packaging machine

2.High measurement accuracy.

3.High reliability: main control system components adopt imported products, and instrument adopts Japanese technology.

4.The mechanical structure is reasonable: the system is free of maintenance and the material is adaptable.

5.Material contact part is anticorrosive material.

Application of Double bucket packaging machine

Blet feeder packing machine suit for weighing filling bagging of 5-50kg(or customized weight) of Mix, flake, block, irregular materials such as compost, organic manure,gravel, stone, wet sand etc. Suit for different type and size of open mouth bags such as woven bags, paper bags, kraft paper bags, plastic bags, sacks, carton box, bucket etc.Sand, coal (0.5cm-10cm), rice, wheat, corn, sesame, feed pellets, wheat bran, sawdust, organic fertilizer, metal pellets, fertilizer pellets, rubber pellets, plastic pellets, PP pellets, PE pellets, inorganic salts, Quantitative packaging of granular materials in industries such as industrial salt, sugar, perlite, iron and steel, chemical industry, light industry, etc. Small particle packaging machine, mainly used for fertilizers, grains, beans, wheat, grains, mung beans, cottonseeds, soybeans, melon seeds, broad beans, castor beans, peanuts, peanuts, soybeans, seeds, pumpkin seeds, adzuki beans, Rapeseed, flaxseed, corn, rice, rice, sorghum, barley, rye, barley, adzuki bean, citrus fruits, oats, flaxseed, bio-pellet, etc.

Scope of application Chemical: resin, paint, pigment, medicine, medicine, cosmetics, fire extinguisher, plastic powder, etc; Grain, soybean milk, egg powder, etc. Traditional Chinese medicine ironmaking industry: ore, titanium oxide, zinc oxide, casting sand, metallurgical powder superhard alloy, electromagnetic material, aluminum powder, various metal powder particles, etc.

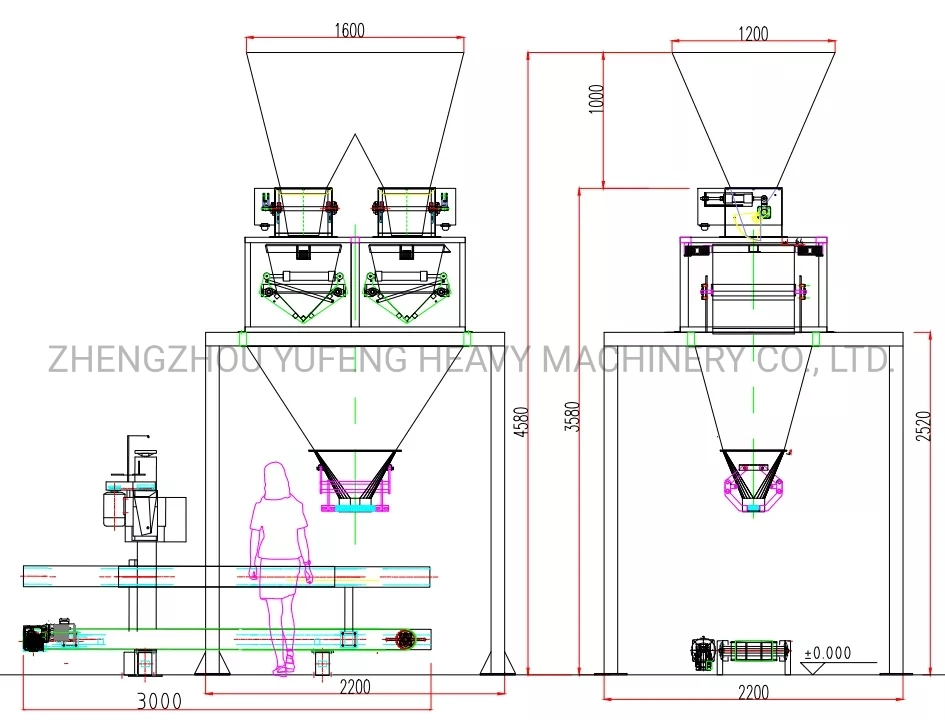

Parameter of Double bucket packaging machine

| Model | DCS-50-D |

| Operation Speed | 600-800 bags/h |

| Weighing Range | 20-50 kg |

| Accuracy Grade | ±0.2% |

| Powder Consumption | 1.5KW |

| Air Consumption | 0.4~0.6 Mpa 1m3/h |

| Machine height | 3044 mm |

Application Double bucket packaging machine

1. Bulk material enters the hopper2. Unloading by electronic scale3. Quantitative filling of pouches4. Bag conveying (equipment)5. Electric seam bag (bag forming)

Case of Double bucket packaging machine

SALES AND SERVICE

Pre-sales service1.Tailor-made efficient technical solutions for you.2.Tell us your needs, we will recommend the machine to you, professionally introduce the machine3.Service consultation in 365 days a year.4.24 hours to respond to messages in a timely manner service During the project1.Standardized precision production of production orders in 8 major departments.2. The operation of the machine will be tested before delivery, video will be given to the customer, and the machine will bechecked and accepted3.The entire production process is visualized, which is convenient to check the production progress at any time.4.The idling machine test is combined with the feeder test - strict quality inspection.After-sale service1. Accepting service consultation in 365 days a year.2. Our after-sales engineer can come at any time for maintenance.3. We will return customers on a regular basis, to ensure proper operation of the production line.4. We provide accessories for all equipment.

CUSTOMER CASE

Very welcome your consultation!

Our Contact